EARLY COAL MINE SAFETY

Roof falls were a major cause of injury and death. Loose rock above the mined out areas was “barred down” by miners using long steel bars. Before miners entered the workings each day it was the job of the fireboss to check for accumulated methane gas. Since methane is lighter than oxygen it rose to the roof of the workings where it accumulated.

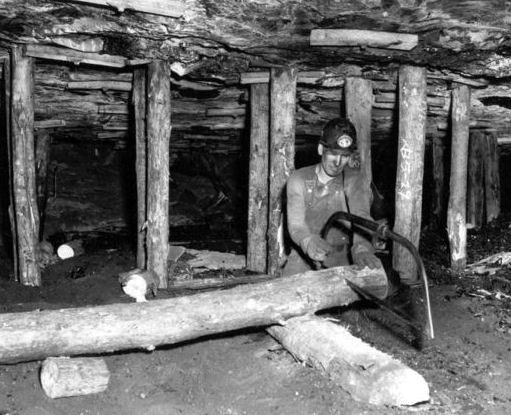

Prior to the development of roof bolting, which began to be used in 1956, the most effective means of preventing roof failures was prop-setting to support the roof in mined out areas. The photo on the left shows miners setting props in the 1890s, while the photo on the right shows miners setting props in the 1940s.

One of the most dangerous aspects of coal mining was the possibility of an open flame, spark or blasting charge igniting methane gas or coal dust. In this 1910 photo miners are picking up a flame safety lamp before proceeding to their work place. The hand-written sign says NO OPEN LIGHTS.

Explosions in coal mines are generally caused by methane gas or coal dust being ignited by an open flame or spark. The best means of controlling methane is through proper ventilation of the mine workings. Coal dust is minimized by applying a dusting of non-combustible rock to all coal surfaces up to within 40 feet of the working face, as seen in this 1960s photo.

Nationwide, in the years 1900 to 1910 there were an average of more than 2,000 coal mine fatalities annually. In 1910, Congress created the U.S. Bureau of Mines within the Department of the Interior to deal with mine safety. By 1912, eight mine rescue stations had been established to provide safety, first-aid and mine rescue training, and to assist in mine rescue efforts nation-wide.

A 1920s Kentucky mine rescue team equipped and ready to respond to a mining disaster.

Mine rescue team underground during a rescue effort following a mine explosion in 1915.

Cutting timber props - Lynch, KY

Mine Rescue Team - Lynch, KY

Consolidation Coal Co. Mine No.207 fire fighting equipment